DC direct current shunt link machines

|

|

| RPM

Model |

1500

kW |

2000

kW |

3000

kW |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

For the high requirements of the modern electrical drive technology with the use of D.C. current with static inverter supply a new conception was created for the operating of motors with a large range of control, so that it works better in an variable environment of quick changing RPM´s during the production process .This is evident by:

1. Good commutation characteristics also free direct current,

2. Spark free and infinitely variable in regular and controlled operation

3. Smaller dimensions, connection dimension according to the

International Electronical Commission, enclosure IP 44.

With our D.C. motor models in the sizes of 80 to 200 according to the International Electronical Commission these demands are fully meet. Whereby not only substantial technical advantages are obtained in relation to the conventional design, but also a volume saving of up to 40 %.We implement our D.C. motors with four totally plated poles, whereby we do not sacrifice the outstanding characteristics of the compensation coil or the commutator.

The main field distortion is suppressed by the compensation coil, so that DIERKING D.C motors also work with perfect commutation in spite of power surges much higher than the rated current.

The four poles model of our D.C. motors with totally plated poles, contributes among other things substantially to the smaller design.

This manufacturing method is favorable for the cooling of the coil by direct heat dissipation over the grey cast iron housing to the cooling fins.

Infinitely variable operation in running environment, also under extreme conditions.

The slots for the admission of the compensation coil are provided with high strewing bar for the increase of anchor circle inductance:

For the improvement of the crest factor (FF) during static inverter supply thereby a smaller auxiliary

inductance (anchor throttle) is needed.In addition noises are to a very large extent avoided.

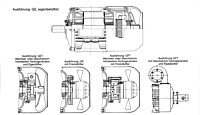

DIERKING D.C. motors with measurement in accordance with the International Electronical Commission are supplied in all designs according to DIN 42 950/4.64.

Combined with the DIERKING transmissions for the low speed range, they form a compact, graceful

designed unit.For the most diverse operation conditions of the electronically controlled technology the D.C. maschine with direct current speedometer or alternating current speedometer can ventilated it self or through a secondary system and be implemented with the most different brakes.

Custom built models are always possible.

We are glad to help you with more information, just contact us.

|

Arthur-Soltau-Weg 4 22889 Tangstedt Germany Tel. +49 40 8541 3862 Fax +49 40 8541 3921 info@dierking-antriebe.de |